You are here:

You are here:

Products List

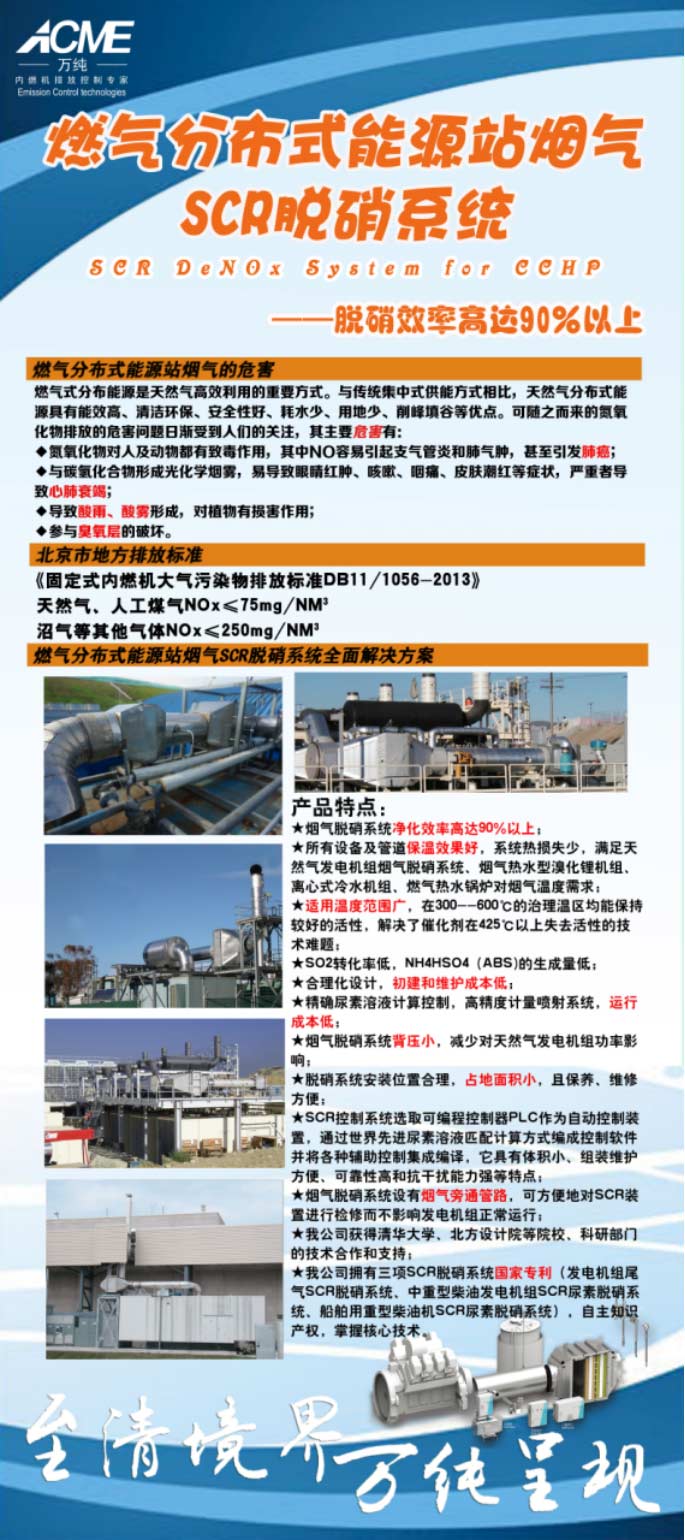

Hebei Hanlan has launched a flue gas SCR urea denitrification system with international advanced technology for distributed gas-fired unit energy stations fueled by natural gas, biogas, gas, rock formation gas, etc. The system can reduce the NOX emission of gas-fired units by more than 90%, and is suitable for the matching use of Jenbacher and other brand gas-fired units with a single unit below 10MW.

The principle of the SCR DeNOx system (SCR selective catalytic reduction system) for CCHP is a device that converts nitrogen oxides (NOX) into harmless nitrogen (N2) and water (H2O) under the action of a catalyst. The NOX in the flue gas after denitration meets the emission requirements.

SCR DeNOx systems for CCHP use the mainstream international SCR technology route for the denitrification of exhaust gases from generating units. It is our own intellectual property technology, i.e. Selective Catalytic Reduction (SCR), which is currently the mainstream international technology for efficient NOX removal from exhaust gases. It is mainly aimed at the NOX in flue gas, at a certain temperature (generally 300℃-580℃), the catalyst will break down the NOX into harmless nitrogen (N2) and water (H2O).

Advantages of SCR DeNOx systems:

1. High efficiency, removal rate of more than 95%, can guarantee the project NOx removal effect.

2. catalyst activity temperature of 300-580°C.

3. High air velocity catalysts, large specific surface area and compact size.

4. Small ammonia escape from the flue gas denitrification system.

5. meeting the use of denitrification and rear waste heat devices.

6. the overall resistance of the flue gas denitrification system does not affect the normal discharge of flue gas.

7. simple structure of the denitrification system, no by-products, easy operation, high reliability, high denitrification efficiency and relatively low one-time investment.

8. It can adapt to the fluctuation of generator operating load, meet the requirements of the number of starts and stops of the unit, and does not cause any interference to the generator operating load and operation mode.

9. the control system can achieve normal operation and monitoring.

10. ensure that the flue gas can be discharged smoothly in the event of a failure of the denitration unit.

11. high degree of automation and good reliability.

12. The system is compact in combination, simple and quick to connect, corrosion resistant and has excellent overall performance.